Optical design, component selection, integration and assembly

Our customer needed a system specifically designed to distinguish the fluorescence signal from two separate wells under illumination within a centrifuge. After a preliminary design evaluation, ASE Optics’ team of optical engineers proposed a solution based on a one-to-one relay for each of the sample wells over a hard aperture and then transmitting the signal from each sample well over a separate photodiode.

After evaluation of this first preliminary design proposal, it was found that the proposed solution was feasible and that the system worked.

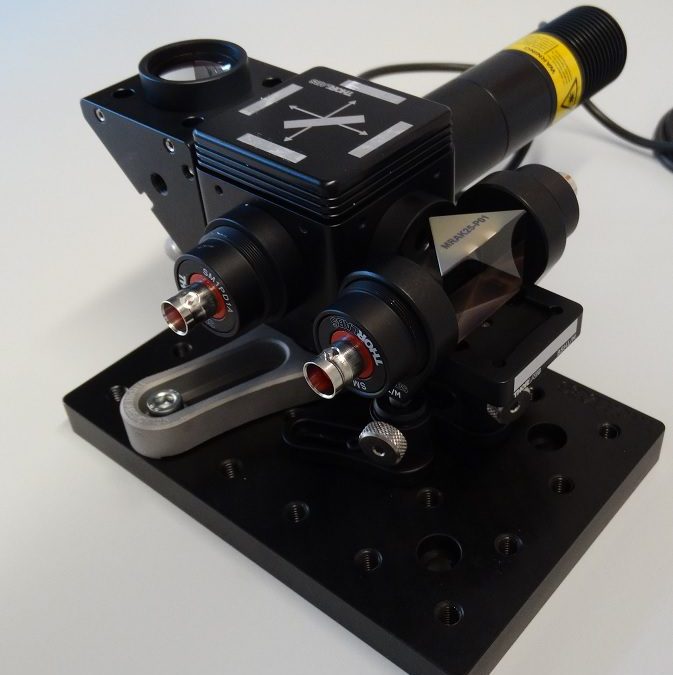

The final design was based on catalog components, combined with a single custom designed and manufactured element: the part in charge of doing the spatial filtering of the signals from each separate well. The resulting signal from well-to-well emission was found to be less than 0.1%.

In only 6 weeks, ASE Optics delivered the desired system to the customer, fully operational, meeting all requirements. This was possible thanks to our work system and the team of professionals that make up ASE Optics.